Introduction

Global supply chains are facing unprecedented challenges. Demand is unpredictable, disruptions are frequent, and customer expectations are higher than ever. To keep up, businesses can no longer rely on outdated systems. They need platforms that are flexible, intelligent, and connected.

This is exactly what Dynamics 365 Supply Chain Management (D365 SCM)—also known as Microsoft Dynamics 365 supply chain management—delivers. It provides companies with the ability to turn traditional operations into agile, data-driven supply chains. Let’s explore what makes Dynamics 365 SCM so impactful and how it is reshaping supply chain management today.

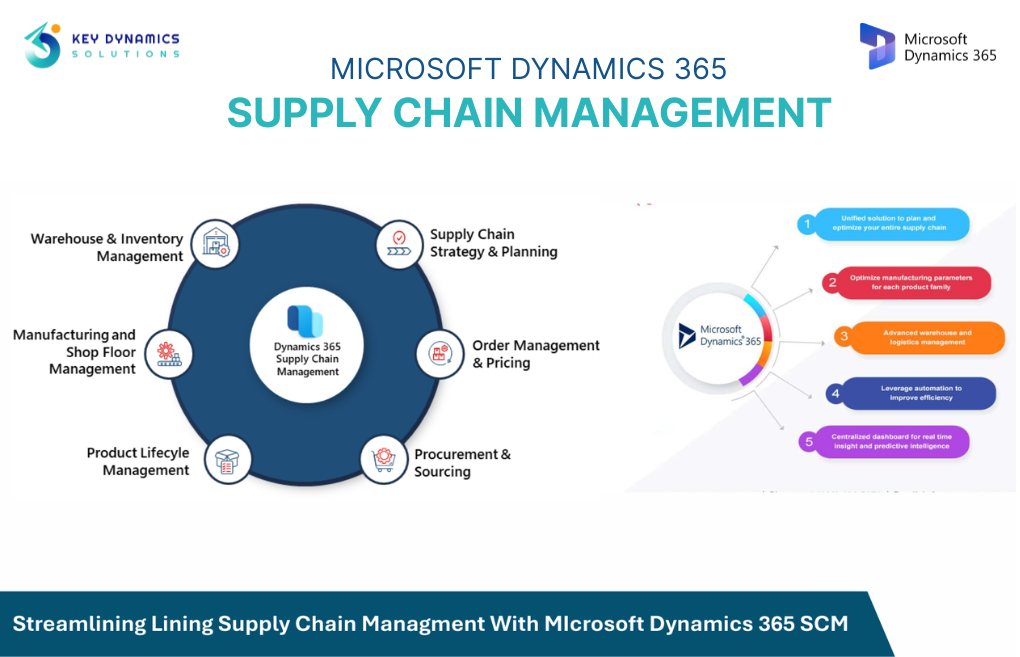

What is Dynamics 365 Supply Chain Management?

At its core, Dynamics 365 SCM is Microsoft’s cloud-based solution designed to integrate every part of the supply chain. It connects procurement, production, inventory, logistics, and asset management into one unified platform.

Unlike older systems that work in silos, Microsoft Dynamics 365 supply chain management links directly with other Microsoft tools like Dynamics 365 Finance, Power BI, and Teams. This creates an intelligent ecosystem where data flows seamlessly, helping teams make better decisions in real time.

Key Capabilities of Dynamics 365 SCM

Procurement and Sourcing

With D365 SCM, organizations can streamline supplier onboarding, automate purchase requisitions, and evaluate vendor performance more effectively. This leads to stronger supplier relationships and better cost control.

Inventory and Warehouse Management

One of the biggest challenges businesses face is maintaining the right stock levels. Dynamics 365 SCM provides real-time visibility across warehouses and locations. This helps reduce overstocking, prevent shortages, and ensure smoother order fulfillment.

Production and Manufacturing

The system supports different manufacturing approaches, whether discrete, process, or lean. With IoT integration, production managers gain better insights into shop floor activities, allowing them to optimize schedules and minimize downtime.

Transportation and Logistics

Efficient delivery is key to customer satisfaction. Microsoft Dynamics 365 supply chain management helps businesses plan routes, choose carriers, and monitor shipments to cut costs and reduce delays.

How Dynamics 365 SCM Transforms Supply Chains?

Real-Time Visibility

Managers no longer have to wait for end-of-day reports. With D365 SCM, they can track inventory levels, production progress, and shipping status instantly. This kind of visibility allows for faster responses when issues arise.

Predictive Planning

The system uses AI to forecast demand and identify risks. Instead of relying only on past trends, businesses can run “what-if” scenarios to see how changes in demand or supply will affect outcomes.

Smarter Automation

Routine tasks like order processing or warehouse picking can be automated, freeing up staff for more strategic work. This not only reduces human error but also speeds up operations across the board.

Greater Agility

When disruptions occur, agility matters most. Microsoft Dynamics 365 supply chain management enables companies to quickly adjust plans, reroute deliveries, or switch suppliers without losing momentum.

Business Benefits of Adopting D365 SCM

Companies adopting Dynamics 365 SCM often see measurable improvements. Operations become more efficient, costs go down, and customers receive better service. With cloud scalability, organizations can expand quickly without the burden of heavy IT investments.

Perhaps most importantly, decision-making improves. Executives and managers gain access to dashboards and real-time insights, helping them act proactively rather than reactively. The result is a supply chain that is not only more resilient but also more aligned with long-term growth goals.

Best Practices for Implementation

Start with a Roadmap

Businesses should begin by analyzing their current processes and identifying areas where D365 SCM can bring the most value. A phased rollout often works best.

Focus on Data Quality

Clean, consistent data is critical. Before migration, companies should review and standardize product, supplier, and inventory information.

Train Teams Early

Adopting a new system requires change. Training employees and involving them in the transition helps drive adoption and minimize resistance.

Pilot Before Scaling

Launching D365 SCM in one warehouse or plant first allows teams to refine workflows before expanding the system organization-wide.

The Future of Supply Chain with Dynamics 365 SCM

The supply chain of tomorrow will look very different from today. Microsoft Dynamics 365 supply chain management is already moving toward more advanced AI, digital twins for simulation, and deeper IoT integration. Sustainability is also becoming central, with tools to measure and reduce carbon footprints gaining importance.

With its flexible and modular design, D365 SCM can evolve with these changes. Companies adopting it now are not just solving today’s challenges—they are preparing for the supply chain of the future.

Conclusion

Modern supply chains demand speed, intelligence, and adaptability. Dynamics 365 Supply Chain Management (D365 SCM) gives organizations exactly that. By uniting procurement, manufacturing, inventory, and logistics in one connected system, it allows businesses to work smarter, reduce risk, and serve customers better.

For any company looking to future-proof its operations, adopting Microsoft Dynamics 365 supply chain management is not just an upgrade—it’s a strategic move toward resilience and growth.

Read Also: The Future Is Responsive AI in Supply Chain Management

Logistics

Logistics  Life Science

Life Science  Healthcare

Healthcare Services

Services Manufacturing

Manufacturing  Banking & Finance

Banking & Finance Retail

Retail E-Commerce

E-Commerce Finance

Finance Supply Chain Management

Supply Chain Management Sales

Sales Customer Service

Customer Service Field Service

Field Service Project Operation

Project Operation Marketing

Marketing Human Resources

Human Resources Business Central

Business Central Data Integration

Data Integration Data Warehousing

Data Warehousing Data Analytics

Data Analytics Data Visualization

Data Visualization Data Governance

Data Governance Big Data

Big Data Looker Studio

Looker Studio Power BI

Power BI Power Apps

Power Apps Power Automate

Power Automate Power Virtual Agents

Power Virtual Agents AI Builder

AI Builder Data Machine Learning

Data Machine Learning Prediction & Forecasting

Prediction & Forecasting BOTs & Virtual Agent

BOTs & Virtual Agent Language Services

Language Services Generative AI

Generative AI Agentic AI

Agentic AI iOS & Android Development

iOS & Android Development Cross-Platform Development

Cross-Platform Development UI/UX Design

UI/UX Design App Testing & QA

App Testing & QA Backend Development

Backend Development